Tools and Die Engineering Technology

The mold industry is an upstream industry. But the number of knowledgeable personnel domestic talent is still lacking. This course was born to produce graduates. With expertise in designing and making molds into the mold manufacturing industry and the manufacturing industry of parts and related products. This cooperative education program combines theories and practices over a 4-month period of on-the-job training in the private or public sectors to improve students’ knowledge and ability in mold and product design and manufacturing using digital technology, computer-aided design, computer-aided manufacturing and computer-aided engineering. The cooperative education program combines classroom learning with real-world work experience. This results in graduates who have practical ideas being able to work, and can integrate the knowledge of mold and product design and manufacturing into their work. This is consistent with the country’s policy of integrating the manufacturing world with digital technology and the Internet of Things. Students are also taught research skills in mold and product design project subjects before going out to practice. Students are given skills in thinking, analyzing, and creating research that can be used for real-world benefits.

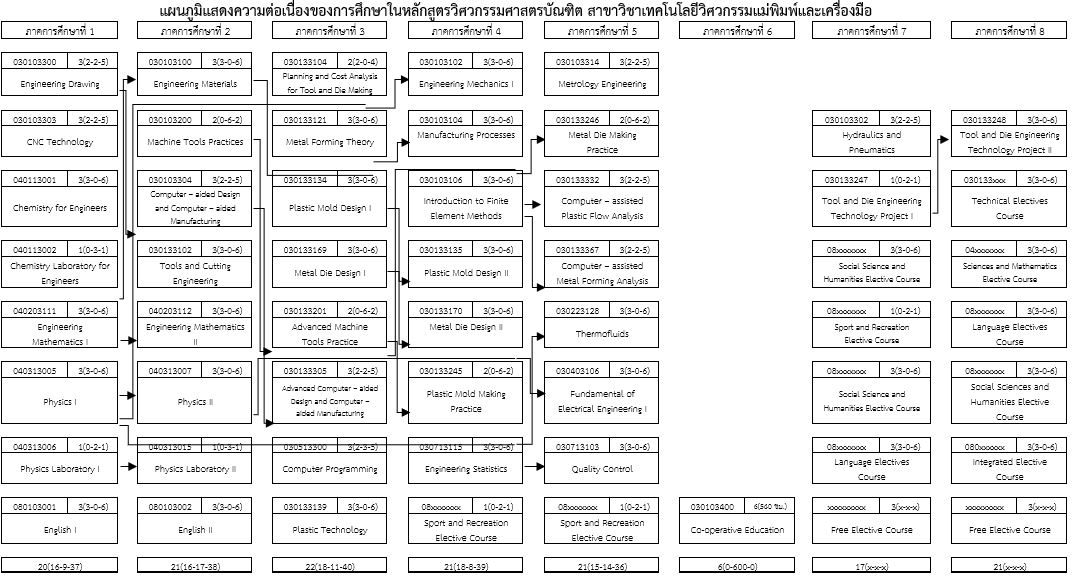

Program 4 years Credits 149 Credits

ELO 2 (S) Be able to identify the relationship of the problem, document search and solve complex problems in tools and die engineering technology. To preliminary summary using principles and tools to analyze mathematics, science and engineering accurately.

ELO 3 (S) Be able to find answers to complex problems in tools and die engineering technology and design processes related to the engineering technology of tools and die. according to the need and requirements of the job taking into account society, safety, health and environmental requirements or professional practice standards

ELO 4 (S) Be able to examine, diagnose and evaluate complex problems of engineering technology of tools and die by making assumptions, design of experiments, analysis, interpretation, data, and synthesis of data to obtain rationally correct conclusions.

ELO 5 (S) Be able to suitable select and apply appropriate and up-to-date techniques, methods, resources, equipment, tools and die engineering technology information, taking into account the requirements and limitations of such tools and equipment. according to the correct principle.

ELO 6 (G) Be able to work with people from various disciplines, and possess leadership with efficiency.

ELO 7 (G) Be able to communicate in engineering, have engineering drawing skills, and Issuing commands and receive work orders clearly and effectively.

ELO 8 (G) Be able demonstrate responsibility for the practice of the engineering profession. in the context of society, the environment, and sustainable development.

ELO 9 (G) Be able to understand and adherence ethics, and engineering ethics based on academic.

ELO 10 (G) Be able to apply knowledge of economics and management in the production process of tools and die technology considering the risks and situations of tools and die industry in the country and the world economy.

ELO 11 (G) Realize the necessity of applying knowledge for self-development in lifelong learning, developing one’s quality of life and live with potential.

– Students must be a graduate of a vocational certificate (Voc. Cert.) in the field of Mechanics, Machine tools, Metal die molding, Injection molding, Machine design, Product technique, or its equivalency in the other fields. (or)

– Students must be a graduate of senior high school (Mattayom 6) in Mathematics-Science and Technology and have completed at least 30 credits of Mathematics-Science and Technology subjects or its equivalency with the regulations of the Ministry of Education. (or)

– Students must be a graduate of high vocational certificate (High Voc. Cert.) in the field of Metal die molding, Injection molding, Machine tool technology, Machine design, or its equivalency. (or)

– Those who do not meet the requirements above will be at the discretion of department of Mechanical Engineering Technology of the Academic Committee. (or)

– Student must have other qualifications according to the regulations of King Mongkut’s University of Technology North Bangkok regarding bachelor’s degree.

| Total Credits | 149 | Credits | ||

| 1) General Education Subjects | 30 | Credits | ||

| a. Languages Subjects

– Compulsory Subjects – Elective Subjects |

12

6 6 |

Credits Credits

Credits |

||

| b. Integration Subjects | 3 | Credits | ||

| c. Social and Humanity Subjects | 9 | Credits | ||

| d. Science and Mathematics Subjects | 3 | Credits | ||

| e. Sports and Recreation Subjects | 3 | Credits | ||

| 2) Specialization Subjects | 113 | Credits | ||

| 1. Core Subjects

– Mathematics and Science Fundamentals Subjects |

45

18 27 |

Credits Credits

Credits |

||

| 2. Professional Subjects

– Compulsory Subjects – Technical Elective subjects – Compulsory Subjects – Elective Subjects – Engineering Fundamentals Subjects – Cooperative Education Subject |

68

23 35 32 3 4 6 |

Credits Credits

Credits Credits Credits Credits Credits |

||

| 3) Fee Elective Subjects | 6 | Credits | ||

Semester 1: June – September

Semester 2: November – February

Summer semester: April – May

Potential Careers after Graduation:

- Production and tools and die maintenance engineering.

- Product design engineering of plastics and metal.

- Quality control and assurance engineering in produce tools and die process.

- Research and development engineering for industrial product.

- Production engineering of plastics and metal part.

- Entrepreneur/Business owner in tools and die field.

- Educational personnel.

- Other occupations related to tools and die

Contact Details:

Division of Tools and Die Engineering Technology

1st Floor Building 62

College of Industrial Technology

King Mongkut’s University of Technology North Bangkok

1518 Pracharat 1 Rd., Wongsawang Sub-District, Bangsue District, Bangkok 10800

![]() +66 2 555-2000 ext. 6428

+66 2 555-2000 ext. 6428

![]() Asst. Prof. Piboon Sinpayakun (pibbon.s@cit.kmutnb.ac.th)

Asst. Prof. Piboon Sinpayakun (pibbon.s@cit.kmutnb.ac.th)

Mr. Narongsak Nithipratheep (narongsak.n@cit.kmutnb.ac.th)

Asst. Prof. Dr. Uten Khanawapee (uten.k@cit.kmutnb.ac.th)

Dr. Sorasak Wongmanee (sorasak.w@cit.kmutnb.ac.th)

Asst. Prof. Manat Hearunyakij (manat.h@cit.kmutnb.ac.th)

Asst. Prof. Vatchara Layluk (vatchara.l@cit.kmutnb.ac.th)

Dr. Sakchai Muangpasee (sakchai.m@cit.kmutnb.ac.th)

Asst. Prof. Dr. Arkarapon Sontamino (arkarapon.s@cit.kmutnb.ac.th)

Dr. Chiwapon Nitnara (chiwapon.n@cit.kmutnb.ac.th)

Mr. Kumpon Tragangoon (kumpon.t@cit.kmutnb.ac.th)

Mr. Tawatchai Maidung (tawatchai.m@cit.kmutnb.ac.th)